Industrial CST Software

Better Surfaces For Metrology. Cleaner Volumes for Defect Detection.

Get Next-Level Image Clarity from your CT Scans.

Experience outstanding reconstruction quality with Varex’s CST toolkit, designed to eliminate artifacts and optimize imaging results. Enhance your systems quickly using built-in corrections, GPU acceleration, and precision calibration tools.

CST Specifications and Features

| RECONSTRUCTION | |

|---|---|

| Algorithms | Statistical (Iterative)Reconstruction (SR) and Feldkamp Backprojection (FDK) |

| GPU Support | Nvidia, multiple GPUs, offload to RAM if VRAM exceeded |

| Tunability | Extensive possibilities on both SR and FDK |

| Air norm | Flat Value, Adaptive, Image based |

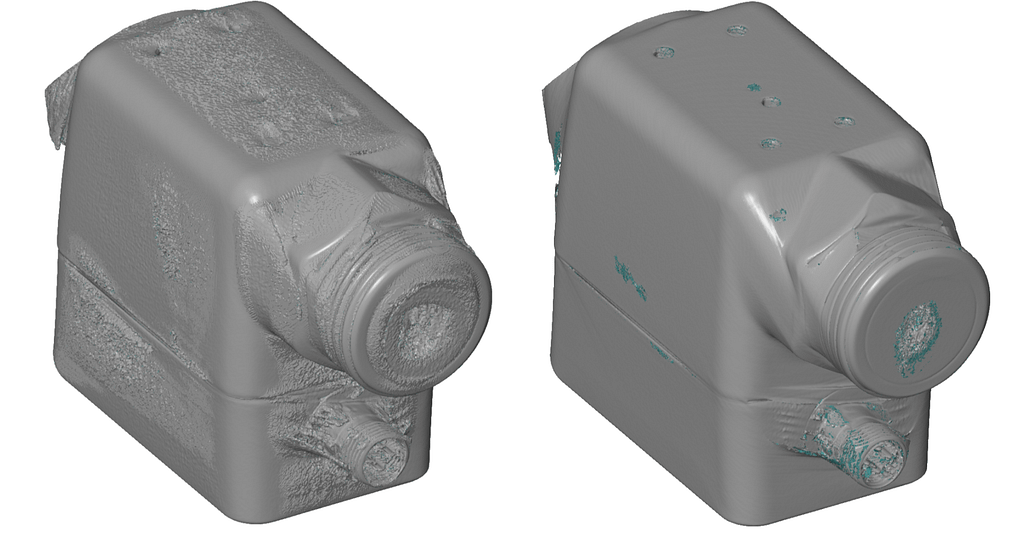

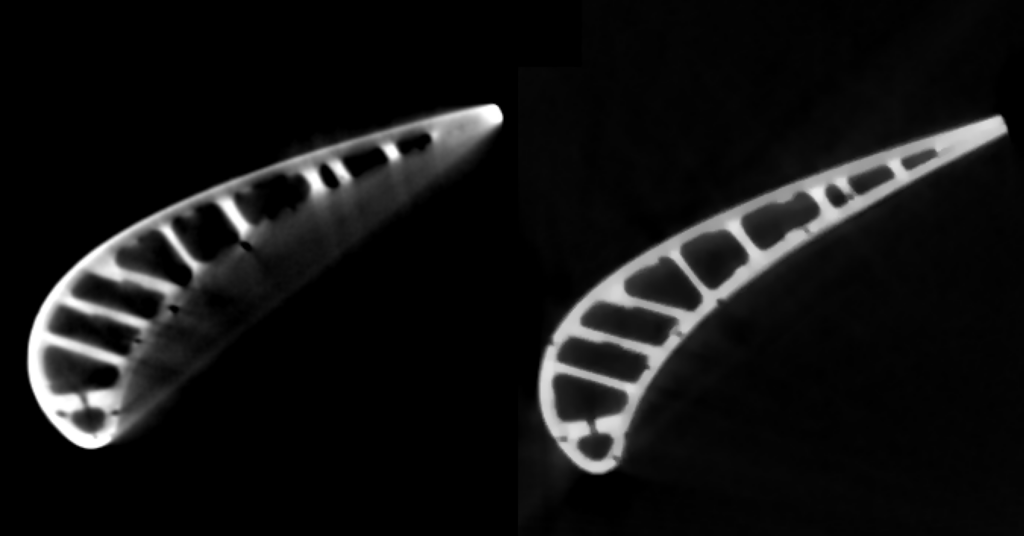

FDK (left) and SR (right) Reconstruction. SR is slower but preserves surface.

| 2D IMAGE PROCESSING | |

|---|---|

| Lag Correction (See Video below) | Dramatically reduce lag content in CT Projections. |

| Beam Hardening | Many material presets, ability to add custom materials |

| 2D Detector Scatter | Varex Detector Scatter Models |

| 2D Object Scatter | Material and Spectrum Dependent Corrections |

| 2D AI Scatter | Machine Learning Corrections available for highly repetitive data (For example Inline CT) |

| Resolution Enhancement | Remove Scintillator Blur with Varex Detector Pixel and Scintillator models. |

CST Lag correction in action – at the end of a 10 minute CT scan.

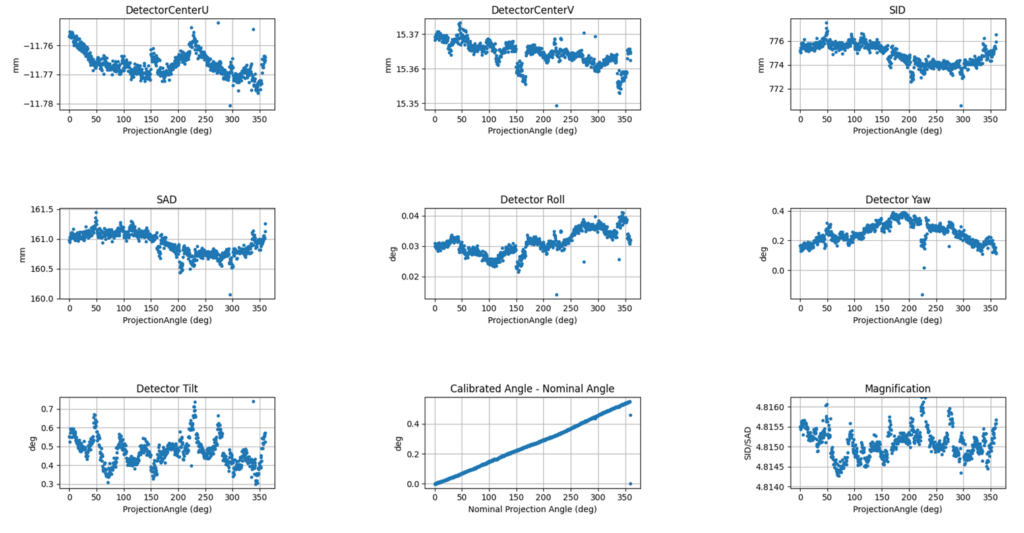

| SYSTEM GEOMETRY CALIBRATION (GeoKit) | |

|---|---|

| Precision Phantoms | Different Sizes of Varex Phantoms available for Standard and Micro-Focus Systems |

| Absolute Values | Geokit determines SID, SAD, Focal Length, Piercing Point, etc for full determination of your system’s geometry. |

| 9 Degrees of Freedom | Position and Orientation of Source, Detector and Rotation Axis. |

| Dynamic Geometry, as well as Static | Full (Absolute value) 9-DOF data available per-frame, for systems with geometries that vary throughout the trajectory. |

Dynamic Geometry results

Microfocus calibration phantom

| VOLUME-BASED (3D) PROCESSING | |

|---|---|

| Material Segmentation | Separate out materials in your scan volume |

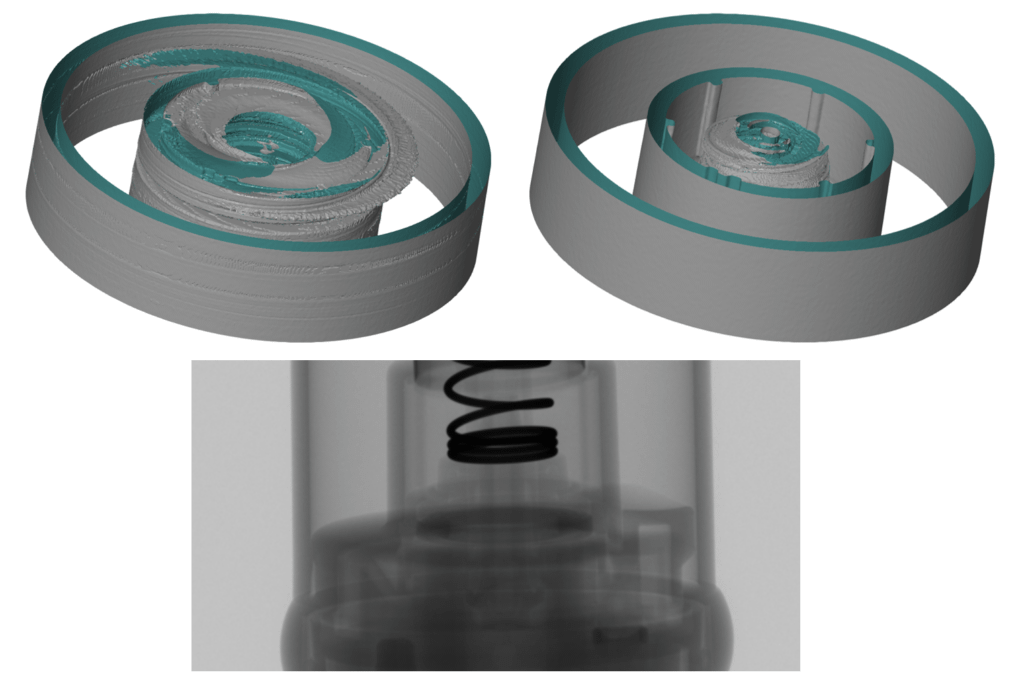

| Metal Artefact Correction (MAR) | Detect Metal and reduce or eliminate negative image quality effects |

| 3D Scatter Correction ” 3D Vsharp” | Hardware free, highly effective, highly adaptive scatter elimination. |

| 3D Multi Material Beam Hardening | Reduce or eliminate beam hardening effects in multi material volumes. |

MAR ON (top right): Measurements enabled on clean surface, in spite of metal spring.

MAR OFF: (top left): Measurements impossible: artefacts from metal spring prevent surface determinations.

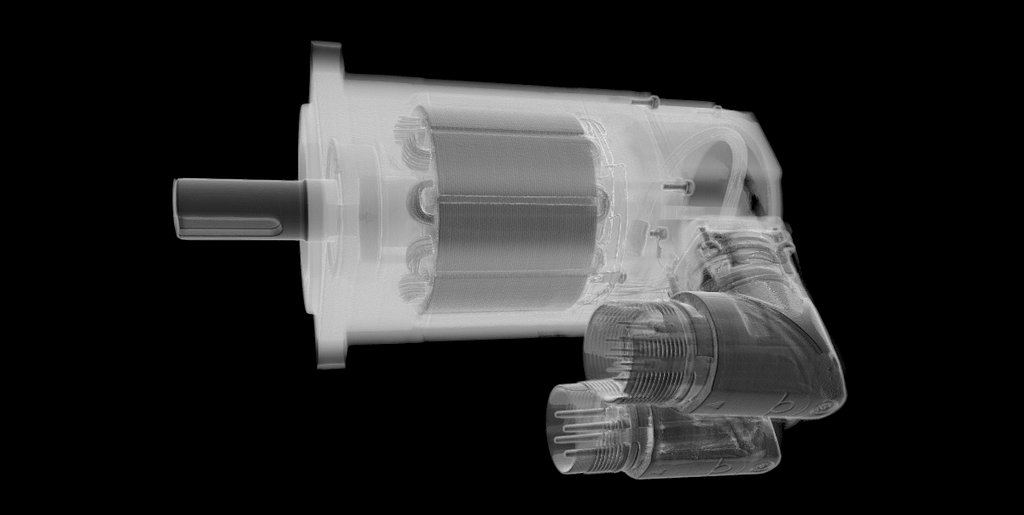

Turbine blade airfoil without and with 3D Vsharp (450kV scan)