Nearly every product available today has gone through many manufacturing stages, including...

From brand protection to recall prevention, Varex Imaging products deliver multiple benefi...

Nearly every product available today has gone through many manufacturing stages, including...

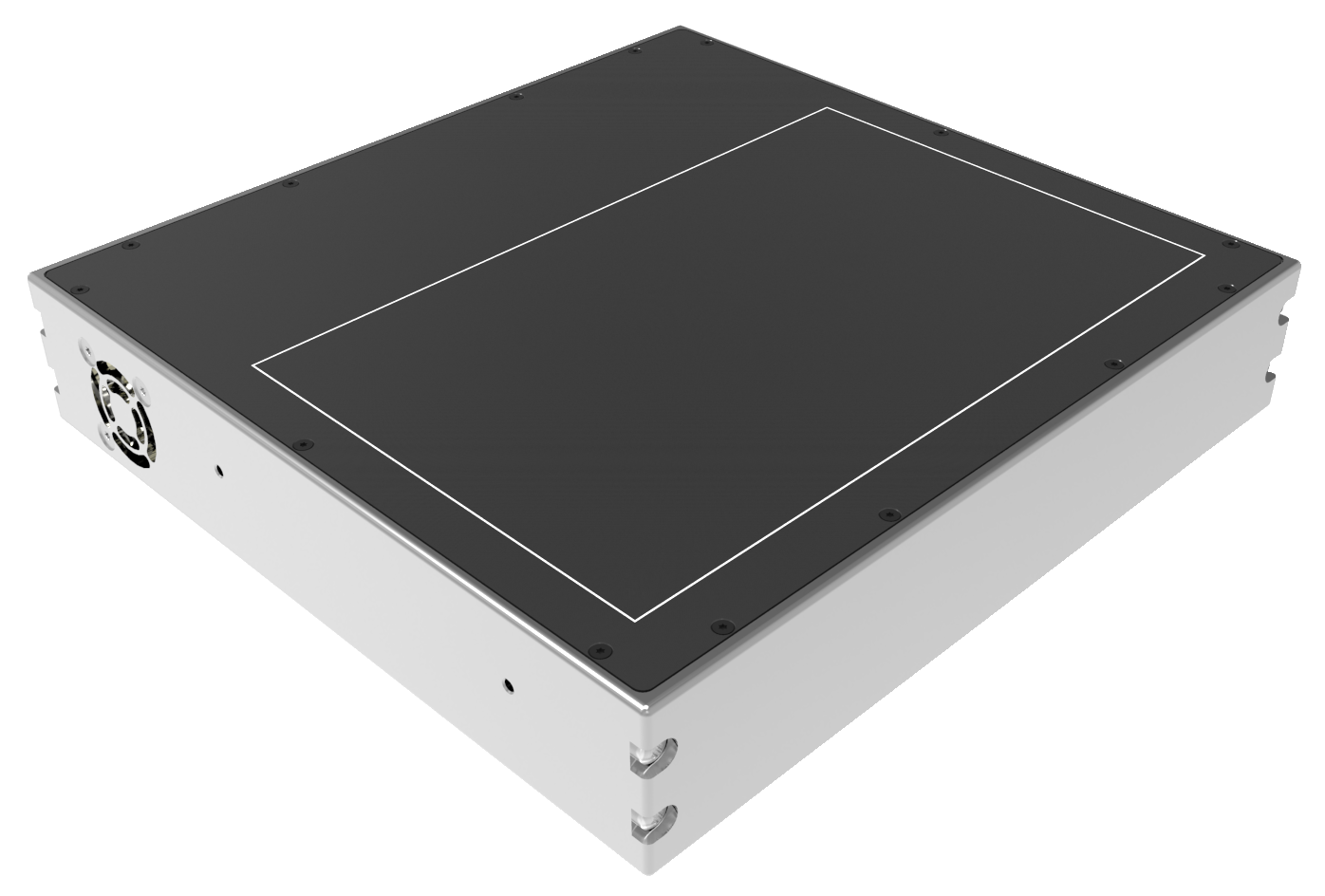

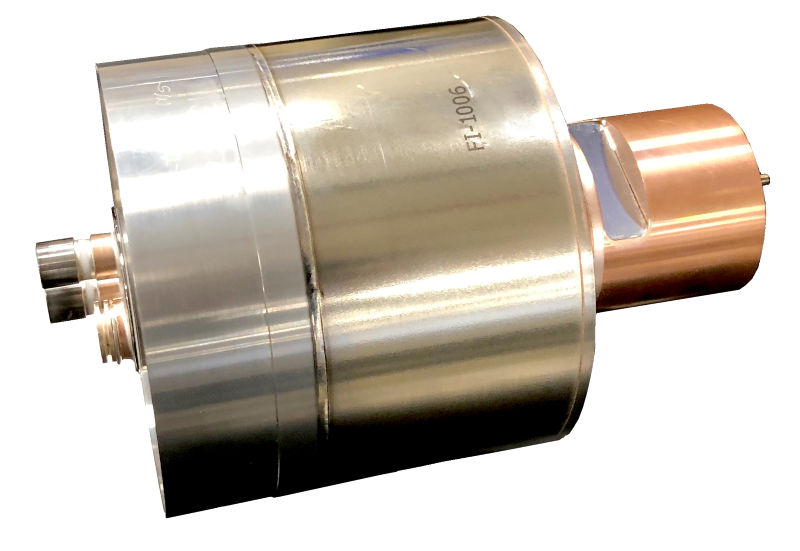

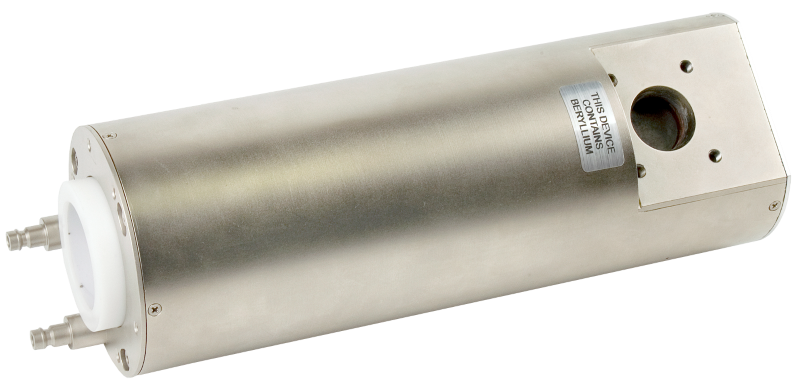

High Energy (HE) scanning allows inspection of highly dense and critical parts such as tho...

Nearly every product available today has gone through many manufacturing stages, including...

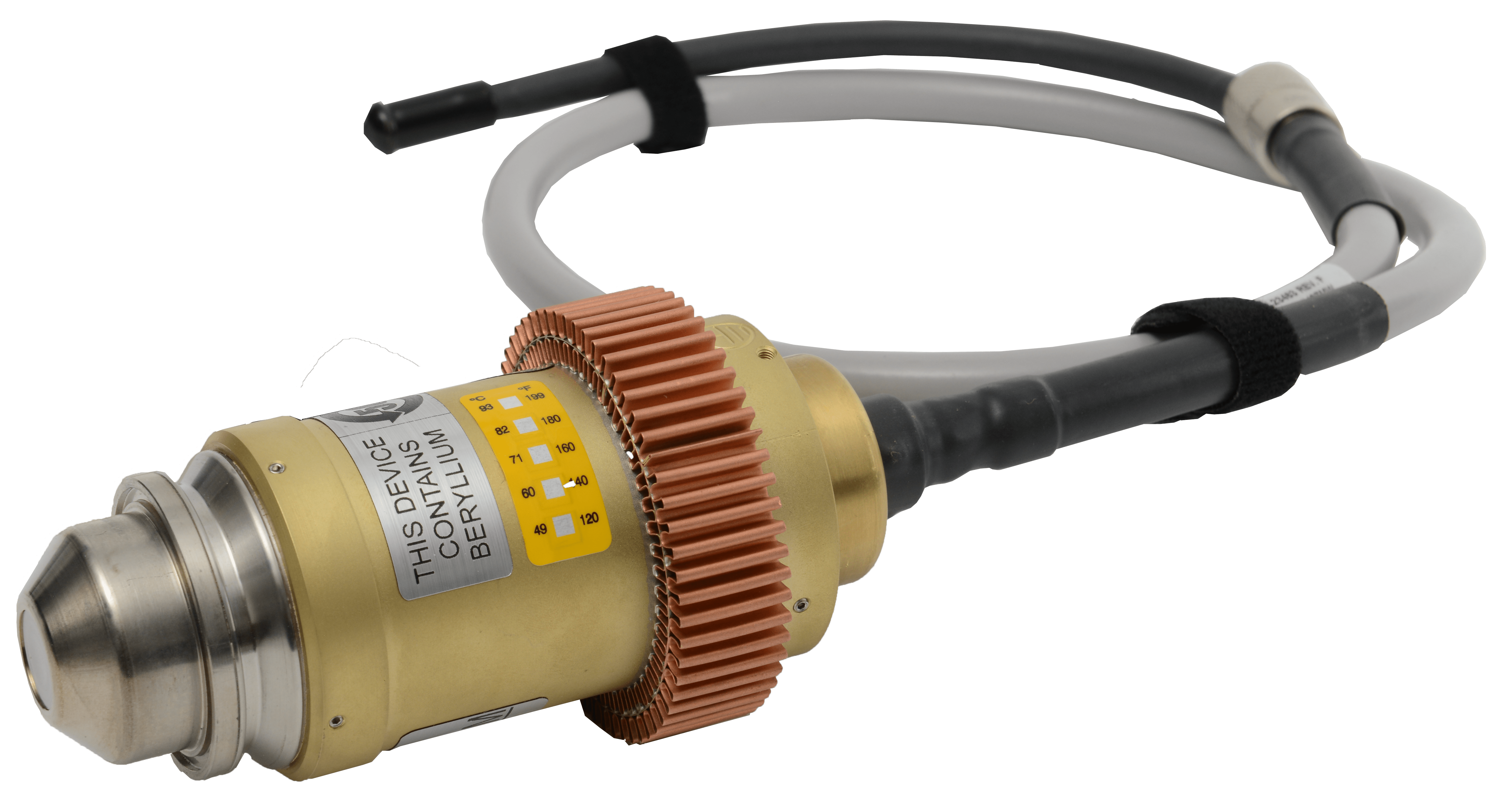

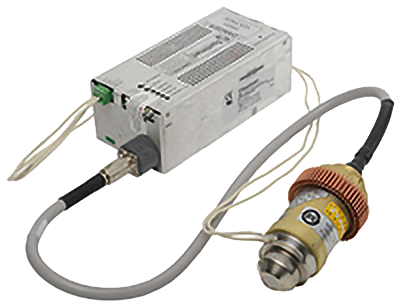

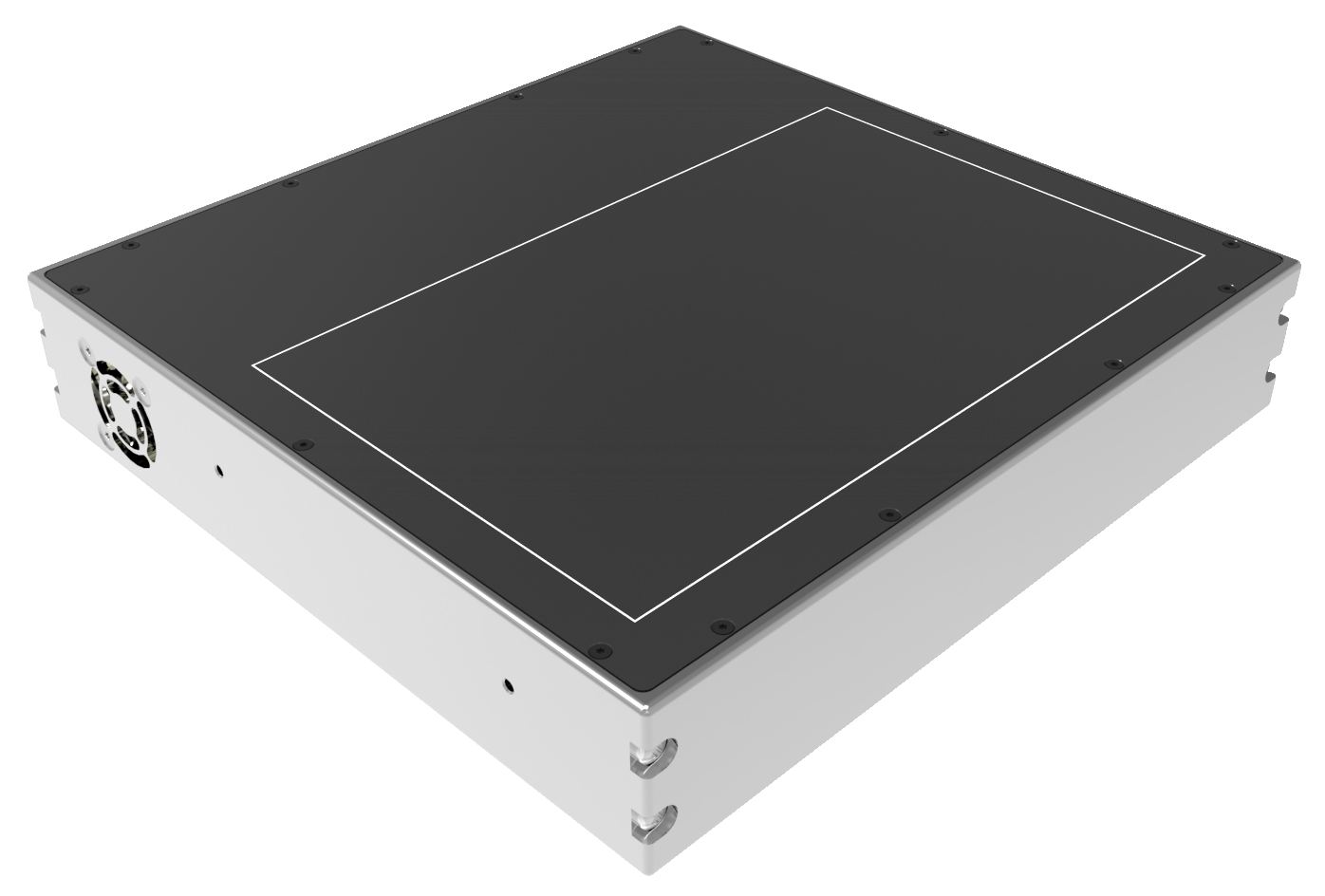

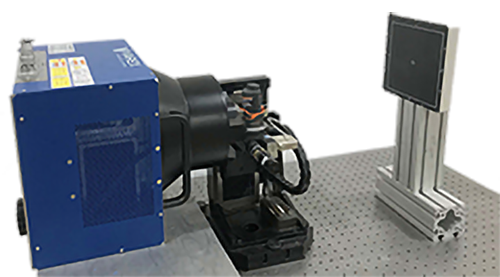

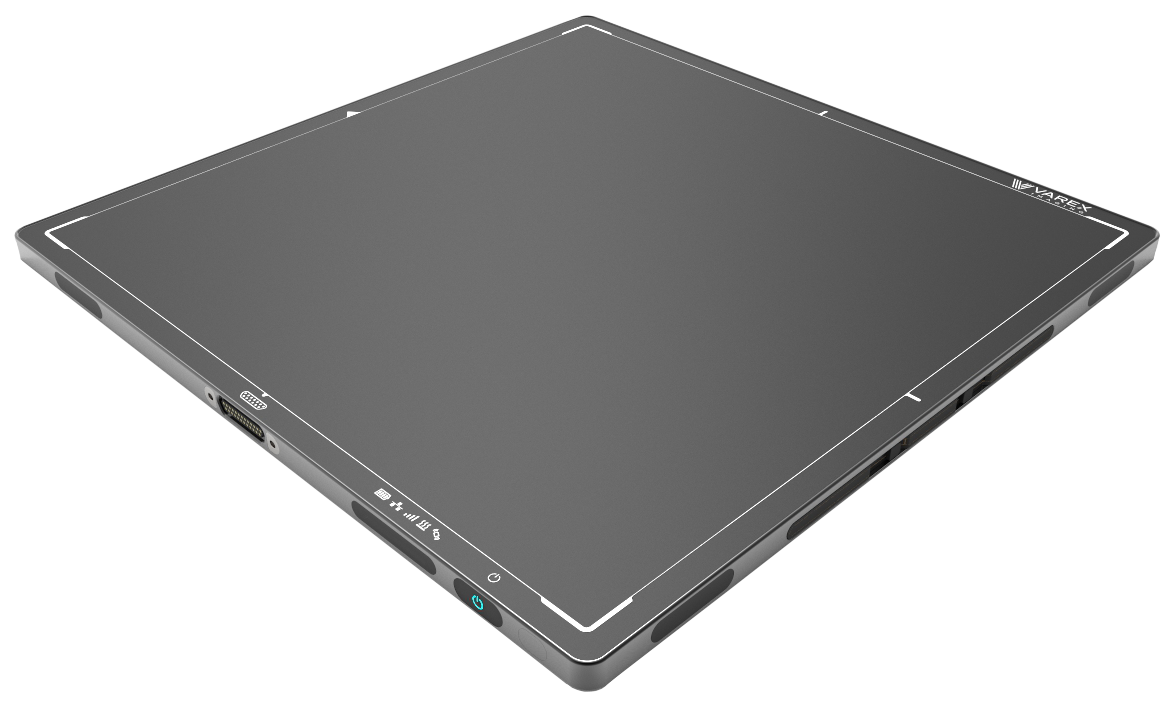

All our portable industrial X-ray components are designed and manufactured to be easily in...

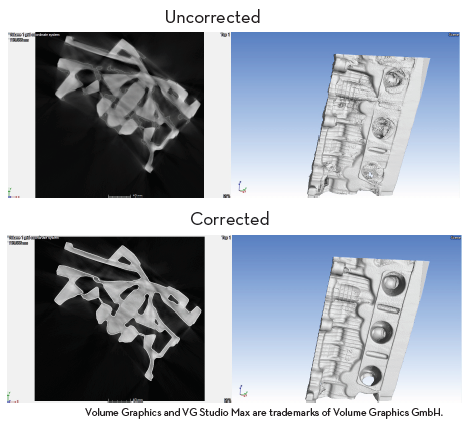

Manufacturers use industrial radiography to check for cracks or flaws in materials. Indust...

02

Contact Us

To receive additional product or service information, please fill in the product inquiry form.